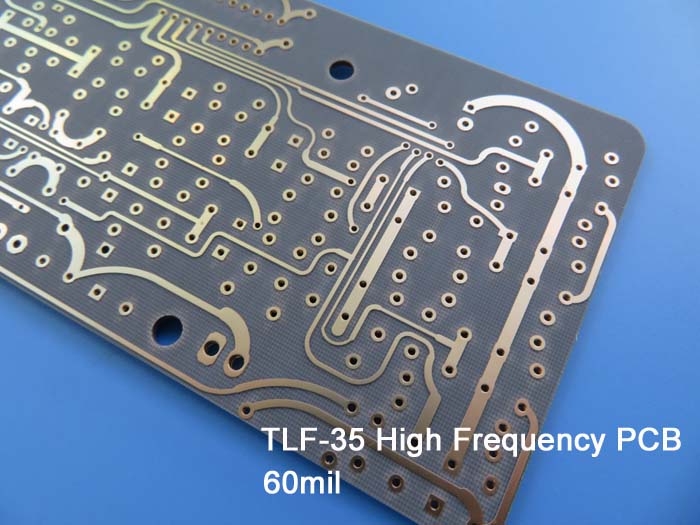

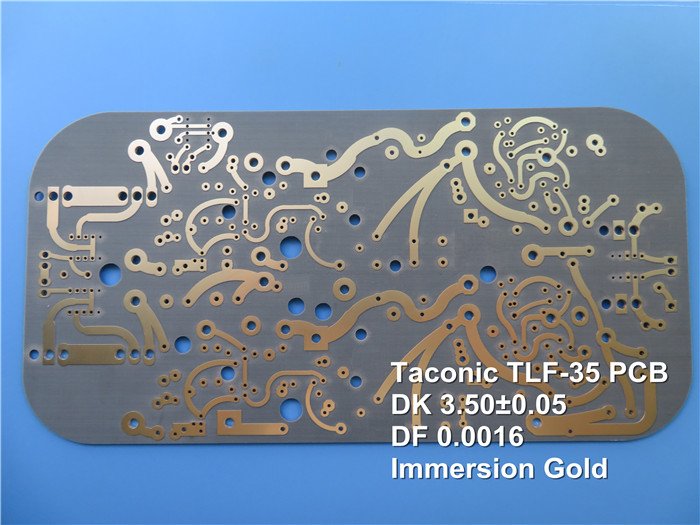

Taconic TLF-35 High Frequency PCB with 30mil, 60mil Thick Coating Immersion Gold, HASL, Immersion Silver and Tin

(PCBs are custom-made products; the images and parameters shown are for reference only)

Hello everyone,

Today, we will discuss the TLF-35 high frequency PCB.

Taconic TLF-35 is an advanced organic-ceramic laminate based on woven glass reinforcement. This material combines ceramic filler technology with coated PTFE fiberglass to deliver exceptional performance.

Key Benefits:

1.Enhanced Phase Intermodulation Distortion (PIMD):

TLF-35 is engineered to achieve improved PIMD performance, making it ideal for compact PCBs used in antenna applications. Its dielectric constant of 3.5 aligns with the required PIMD levels.

2.Superior Plated Through Hole (PTH) Quality:

This material demonstrates enhanced PTH quality, resulting in stable hole walls and insulation resistance, even for smaller drilled holes.

3.High Frequency Stability:

TLF-35 is designed to provide excellent performance at high frequencies, ensuring reliability in demanding applications.

4.Low Moisture Absorption:

With an ultra-low moisture absorption rate and low dissipation factor, TLF-35 minimizes phase shifts across frequencies, contributing to stable performance.

5.Cost-Effective Solutions:

This laminate offers a low-cost option for high-volume commercial microwave and radio frequency applications.

Typical Applications:

Antennas

Power Amplifiers (TD-SCDMA, WCDMA, LTE, WLAN, etc.)

Low Noise Amplifiers (LNA) and Repeater PAs

Passive RF Components (Filters, Couplers, etc.)

PCB Capability (TLF-35)

PCB Capability (TLF-35) |

|

PCB Material: |

Organic-ceramic, Woven glass reinforcement |

Designation: |

TLF-35 |

Dielectric constant: |

3.5 |

Dissipation Factor |

0.0022 10GHz |

Layer count: |

Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

30mil (0.762mm), 60mil (1.524mm ) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated etc.. |

We can supply TLF-35 high frequency PCBs with:

Copper weights: 1oz and 2oz

Thickness: 0.8mm and 1.6mm

Maximum panel size: 400mm x 500mm

Surface finishes: Bare copper, HASL, ENIG, Immersion tin, etc.

Bicheng specializes in providing prototypes, small batch orders, and mass production services.

If you have any questions, please feel free to contact us.

Thank you for reading.

Appendix: Typical Values of TLF-35

TLF-35A Typcial Value |

|||||

Property |

Test Method |

Units |

Value |

Units |

Value |

Dielectric Constant @ 1.9 GHz |

IPC-TM650 2.5.5.5.1 Mod |

|

3.50 ±0.05 |

|

3.50 ±0.05 |

Dissipation Factor @ 1.9 GHz |

IPC-TM650 2.5.5.5.1 Mod |

|

0.0016 |

|

0.0016 |

Dissipation Factor @ 10 GHz |

IPC-TM650 2.5.5.5.1 Mod |

|

0.0022 |

|

0.0022 |

Water Absorption |

IPC-TM 650 2.6.2.1 |

% |

0.03 |

% |

0.03 |

Peel Strength (1 oz. copper) |

IPC-TM 650 2.4.8 |

Lbs./linear inch |

10 |

N/mm |

1.8 |

Volume Resistivity |

IPC-TM 650 2.5.17.1 |

Mohm·cm |

2.0 x 1099 |

Mohm·cm |

2.0 x 109 |

Surface Resistivity |

IPC-TM 650 2.5.17.1 |

Mohm |

3.0 x 108 |

Mohm |

3.0 x 108 |

Flexural Strength Lengthwise |

IPC-TM 650 650 2.4.4 |

psi |

13000 |

N/mm2 |

90 |

Flexural Strength Crosswise |

IPC-TM 650 650 2.4.4 |

psi |

13000 |

N/mm2 |

90 |

Thermal Conductivity |

IPC-TM 650 2.4.50 |

W/m/K |

0.37 |

W/m/K |

0.37 |

x-y CTE (50 ~ 150℃) |

IPC-TM 650 2.4.41 |

ppm/℃ |

9-12 |

ppm/℃ |

9-12 |

z CTE (50 ~ 150℃) |

IPC-TM 650 2.4.41 |

ppm/℃ |

80 |

ppm/℃ |

80 |

Flammability |

UL-94 |

|

V-0 |

|

V-0 |